Neuman USA has been in the impact-extrusion business for over 35 years. Neuman USA knows impact extrusion. We have created many of the techniques used in this manufacturing process.

Impact extrusion consists of three primary approaches: Reverse Impact, Forward Impact and Combination Impact.

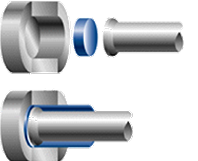

Reverse Impact

A lubricated slug is placed in the die cavity and struck with the punch, forcing the metal to flow out of the die and around the punch.

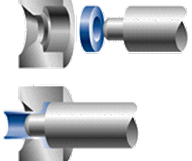

Forward Impact

Metal is forced through the orifice of a die by the action of a punch, causing the metal to flow in the direction of punch travel. The punch fits the walls of the die so closely that no metal escapes backwards.

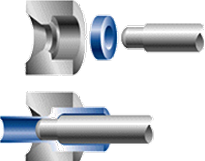

Combination Impact

Combines forward and reverse metal flow and is used to produce complex shapes. A lower punch may also be incorporated with an upper punch so the metal is forced upward into the punch until the cavity is filled.