Structural

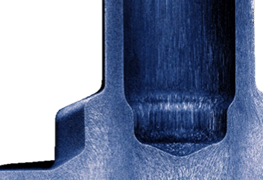

Homogeneous structure, with no pores or cracks. No leakage testing required. There are no draft angles, no parting lines or fire cracks.

Strength

Increased strength with reduced wall thickness and reduced weight, making it a perfect process and material for automotive and high-stress applications, even compared to steel.

Performance

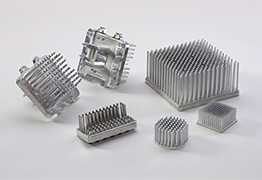

Excellent cooling performance, based on material choice and homogeneous microstructure. Components manufactured using impact extrusion process have a 30% greater heat dissipation, which allows for them to either dissipate more heat or for them to be smaller and lighter in design.

Technical

Production

Up to 300 strokes per minute with accuracy ensures impact extruded parts of the highest quality. It’s the perfect choice for high volume production.

General Cost

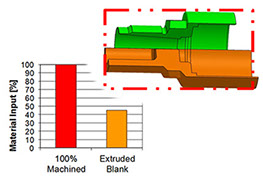

Less machining time (in most cases), lower, one-time tooling costs and less waste means lower overall costs.